For everything the music can give...The journey to develop the V-Cap CuTF (Copper Foil Fluoropolymer Film) series capacitors was inspired by my obsession to tap into that special magic found in the soul of the music. Too often, passive components strip the color from the performance, or add colorations of their own. Cold, sterile, lifeless sound with flat response to bat's ears doesn't get us there. Nor does fat, bloated, "Let's make a new kind of ugly" sound either. We audiophiles have many names for it; pace, rhythm, timing, swing, etc... But there really aren't words to describe the near out-of-body experience we get when we are connected to the soul of the music. That's our Holy Grail- our pot of gold at the end of the proverbial rainbow. Of course, gold is never found at the end of a rainbow. You must prospect for it, and do a whole lot of digging. We have. After nearly 5 years of intense R&D, I am pleased to announce the new V-Cap CuTF series- an audio signal capacitor that will take you to the Soul of the Music...™. A relentless pursuit of the performanceEarly on, we were convinced that one of the keys to better performance would require the use of pure copper foil. However, five years ago, the copper foil of the purity and precision needed to make the capacitor we envisioned, just didn't exist. When we found it, the resultant domino effect led us on a journey that would reexamine ALL current processes and materials, and work with our vendors to explore even better ways of constructing an audio capacitor. Given the many challenges, most bottom-line driven companies would have long abandoned the effort. In the middle of a Global Recession, it was madness to pursue a high-end product that would appeal to a tiny percentage of the overall capacitor market. But with our goal in sight, there was no turning back. It was unthinkable to settle for anything less than fully connecting to the soul of the music... Real people... Real ears... Real music...Over the years, the V-Cap team has developed partnerships with a select group of cutting-edge companies. We turned to them to help develop the materials and processes necessary to manufacture the new CuTF series to our own exacting tolerances. Throughout the process, we drew upon the expertise of some of the world's most respected engineers and scientists, as well as veteran production personnel and master capacitor winders. Each of them made invaluable contributions, and each took us a step closer to the soul of the music... After numerous prototypes, internal evaluations, and multiple rounds of beta testing by audiophiles, musicians, OEM's, and hardcore cap-rolling-o-holics, there became a point where we knew we nailed it. Years of blood, sweat, tears, were washed away by comments like: "...unseen-before combination of extreme body, density with utmost detail", "A passive component that's truly passive.", "A new league of capacitor. The ability for transfer of musical emotion is outstanding.", "Every single time I listen to the new V-Cap, it has the dynamics and sharpness of a Ferrari and luxury and plushness of a Rolls-Royce.", "This capacitor simply disappears from the circuit.", and "as a professional pianist: I clearly hear the most accurate sounds of Steinway among any audio system I owned or auditioned. As a matter of fact, the CuTF is "officially" the best cap in the world, in my book..." etc... While they must remain anonymous, we'd like to extend our sincere gratitude to all of the individuals who contributed to the development of this new V-Cap. From the engineers, production staff, and dedicated master winders, to the musicians, recording engineers and audiophile beta testers who generously donated their time and effort to evaluate this new series- YOU are part of this new V-Cap's heart and soul. Thank you.

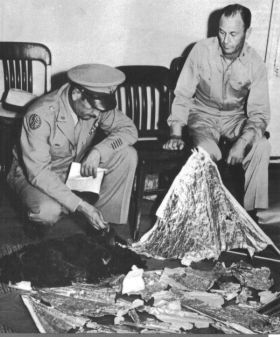

No, our foil isn't sourced from the 1947 Roswell, N.M. crash site. Nor is it rolled on the thighs of Supermodels. However, even a busload of reverse-engineering types headed for Area 51 won't be able to duplicate the superb craftsmanship, bleeding-edge processes, and state-of-the-art materials involved in the production of the V-Cap CuTF capacitors. Here's just a glimpse behind the construction of the V-Cap CuTF series- with a few items left out, of course. Reverse engineers need jobs, too...

A truly unique product for the audiophile who demands extreme performance The end result of this journey is a capacitor of purity, delicacy and power. A capacitor built to the same extraordinary standards as the OIMP and TFTF series- but leveraging all the goodness of pure copper foil, the innovation of some very, very smart people from around the World, and the experience of experienced, dedicated American craftsmen. Just a reminder- the V-Cap CuTF is NOT a “rebrand” or relabeling of an already existing product, but a unique capacitor design that has been meticulously engineered and handcrafted in the U.S.A. In fact, there are so many different suppliers of materials and processes, there is only one person on the planet who knows how all the dots connect, and he's not telling... Every V-Cap capacitor is inspected, tested, and pushed to the edge of extreme conditions, to simulate the harsh environments commonly found in tubed electronics. This ensures long life, reliability, and the ultimate in performance. In fact, V-Cap capacitors are manufactured to such high standards, they are backed by a lifetime warranty to the original purchaser (when purchased from authorized dealer or OEM). V-Cap CuTF Dimensions and Pricing

Prices are in U.S. dollars, and based on total pieces of an individual value/voltage. If you are an OEM or component modification professional, please contact us for pricing

* "V-Cap", "CuTF", "TFTF", "OIMP", "Reference Grade", "Elite Reference", "to the Soul of the Music..." and "Variable Stage Quadrant Dielectric" are trademarks of VH Audio, Inc. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||